My experience converting a van

This article is not going to be a guide on how to convert your own van. It is mostly a collection of notes and information that I put together during the process of buying and converting my own van. I will explain how I decided on a vehicle, designed my own conversion kit, and built it using simple tools and no workshop available.

I hope this can help other people to join Vanlife too!

The research

The first and most important part of this project was figuring out what my requirements were and therefore what kind of vehicle I was looking for. Vans can go from as tiny as a Fiat Fiorino, all the way up to ex-school buses converted into flats on wheels. Normally, bigger vans are more suitable for people that are planning on living in them all the time, whereas I was looking for something more suitable for weekends off, up to maybe a fortnight. Most of the vans on the market also come with 2/3 seats max, while I liked the idea of being able to use it as a normal 5-seater car. Parking was also an issue for me, and I wasn’t looking forward to re-learning how to drive a massive vehicle around the narrow single-lane streets of Bristol. Vans are also typically more expensive to insure and tax, and if I could save on that it would surely be better. To summarise my requirements:

- Can be used as replacement for a car

- At least 4-5 seats

- Easy to drive and park

- Reasonable fuel consumption

- Easy to insure/tax

- Be as stealthy as possible

So, after some vandering around Reddit, I found out about a category of vehicles called MPVs, or Multi-Purpose Vehicle (more like Many-People, if you ask me…). MPVs are cars that are created to maximise the interior space and often have even more than 5 seats. They might look as big as SUVs, but since they’re not designed to drive off-road, they have less ground clearance and therefore more space inside. Some examples of MPVs are Ford S-Max or Ford Galaxy, Citroen Berlingo, Volkswagen Sharan, Fiat Doblo…

Conversion style

MPVs seemed like the best compromise between a car and a van, but how do you convert one without losing the seats? After some research, I ended up on the alternative campervans website of Amdro, which produces the so called “boot jump”. The boot jump is a compact and smartly designed structure that fits in the boot of your car. When you need it, you simply lower the seat back of the rear seats, and the boot jump unpacks into bed, table, lounge and kitchen while simply sitting in the back of your car when you don’t need it. If you need to use the boot, you can simply slide the structure out of the car and restore its normal functionality.

I thoroughly fell in love with the design and decided that this was going to be the base for my conversion, but there was one problem that I had to face… It’s expensive. Like really expensive. The standard model sells for a bit less than £2000! Plus, where’s the fun in buying something already made? After a simple Google search of “diy boot jump” I realised there were tons of different interesting design ideas and I only had to pick one and build it. Great!

Pros:

- Cheap and easy to build

- Completely removable

- Does not require any permanent modification to the car

- Kitchen drawer can be accessed without opening the entire structure

- Can be used while carrying up to 5 passengers

Cons:

- It takes 3-5 minutes to set up open

- You need to open the boot to open the kitchen drawer (not ideal in rain or cold)

- Not really practical to open just for a very quick nap

- It (usually) requires you to move both front seats forward and lower the back

- Space occupied by car’s rear benches is lost when the conversion is used

Choosing the right MPV

After deciding I was going to get an MPV and convert it using a boot jump, I started looking into specific vehicles that would be compatible with boot jumps. Although the concept can be applied pretty much to any car (Honda Jazz, Volvo), my main requirement was the ability to sit upright at the table, so that I could do some work from remote if I had to. A very useful resource that I used a lot during my research was RiDC (Research Institute for Disabled Consumers). Their search tool allows you to check every possible measurement inside a car and allowed me to easily discard some MPVs that were not compatible with my height requirements.

A good starting point for my research of the perfect vehicle was the list of cars supported by Amdro, which includes: Citroen Berlingo (or Peugeot Rifter, or Partner Tepee, they’re all the same car…), Renault Kangoo, Volkswagen Transporter, Volkswagen Caddy, Ford Tourneo and Fiat Doblo. After checking availability on the second-hand market for these cars, and especially the price, I realised that the most likely candidates for me were the Citroen Berlingo and the Fiat Doblo, both vehicles for which there’s a ton of DIY conversion tutorials on the internet.

WAV

As soon as I started digging deep into the second-hand market for Berlingos and Doblos, I realised that the majority of these vehicles sold are converted as WAVs, or Wheelchair Accessible Vehicles. There’s no standard conversion around, but the average meaning of WAV is that the vehicle is heavily modified to have a ramp (manual or electric), which is often permanently welded onto the chassis. The car is also lower on the ground, the fuel tank is replaced with a smaller one to allow for higher ceiling room and the back seats are either removed completely or replaced with smaller ones on the sides. The problem with WAVs is that they’re not easily compatible with the boot jump: the whole point of the boot jump is that you simply lower the back of the rear seats, open the bed and you’re good to go. Since every WAV is different, I would have had to come up with a heavily customised solution. WAVs are probably fine if you’re planning on doing a permanent conversion, but the amount of work involved didn’t really appeal to me, so I excluded this possibility.

Another really annoying fact is that they’re not really properly classified on Autotrader, which means that you manually need to inspect the pictures to discard them. An easy way to recognise them is to look at the rear bumper: if it’s got vertical inserts, that’s the bit where the ramp comes down and it’s going to be a WAV. The only main advantage I could find of buying a WAV compared to a normal car is that they normally come with ridiculously low milage while selling at the same price as the normal ones.

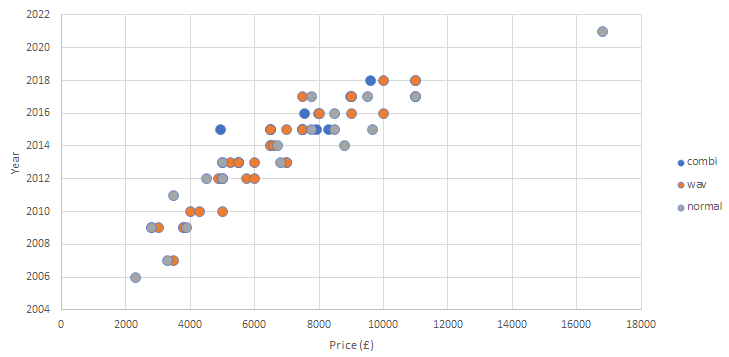

Price vs age vs mileage

The next step towards buying a van was deciding on a range of mileage, age, and price that I was willing to accept. Since I had very little experience buying cars, I started doing what I feel the most comfortable with: plots.

I looked at all the cars on sale (Fiat Doblo) and plotted them by year and price. Although mileage does have an impact on price, the main influencing factor for the price was age. From this plot, I could see that the price increases almost quadratically with the year. Looking at the data, I decided to buy something in the range of 2012-2013, which meant a budget of £4k to £6k.

With these parameters in mind, I managed to reduce my search space drastically, which made my life a lot easier. I was looking for a 2012-2013 Fiat Doblo or Citroen Berlingo between £4k and £6k with reasonable mileage and in good conditions, so I set up an alert on Autotrader and started waiting. After checking in person a few Doblos and Berlingos, I realised that the Doblo was slightly bigger and taller, so I decided to narrow down my search to the Fiat car.

After 2 months since when I started my research, here she came:

Because of COVID-19 regulations, I couldn’t see the car before buying it and it was delivered directly to my address. Luckily, the dealer kept their promise and the car was in as good condition as they mentioned.

The conversion

Now that I had a car, it was time to start the conversion. How do I build a boot jump without any tool, workshop space and practical skills working with wood? I didn’t plan to build something up to the commercial standards of Amdro, but I didn’t want to bodge it either. The first problem was buying and cutting the wood to size. What most people normally do for their conversion is buying a proper electric saw, buy a few large sheets of ply and cut the wood to size by checking the measurements as they go. Since I didn’t have space for a big saw, nor experience cutting wood in a straight line, I decided to ask a woodshop here in Bristol to cut it for me. For just £20 extra on top of the price of the wood, they would cut all the pieces that I wanted, the sizes that I wanted.

The main problem with following this approach is that I needed to have a very precise design in mind, with all the right pieces and measurements written down to the millimetre, no room for mistakes! So I installed Fusion 360 which, to my surprise, is free, and started searching YouTube tutorials on “how to design furniture in Fusion 360”. One important thing that I did while creating my design was making it as parametric as possible. A parametric design allows you to create a flexible model that updates all its parts automatically when you change some measurements. By doing so, I could create my design without paying too much attention to the size of the car, and I could take precise measurements later on.

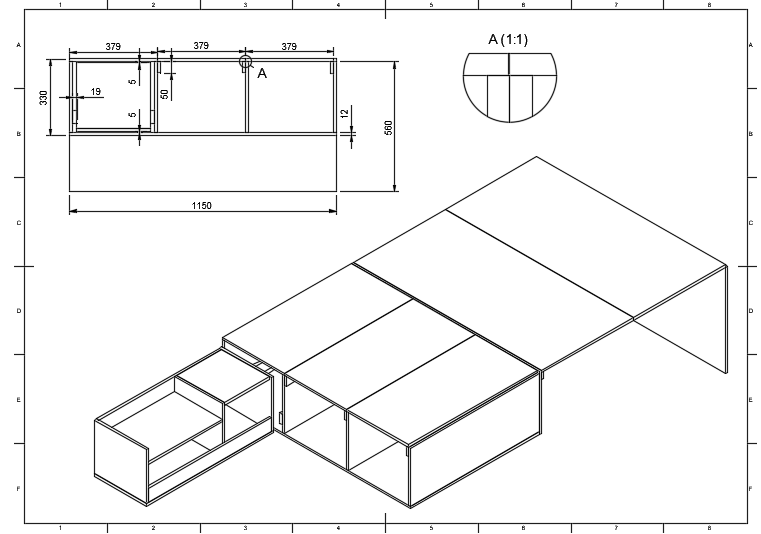

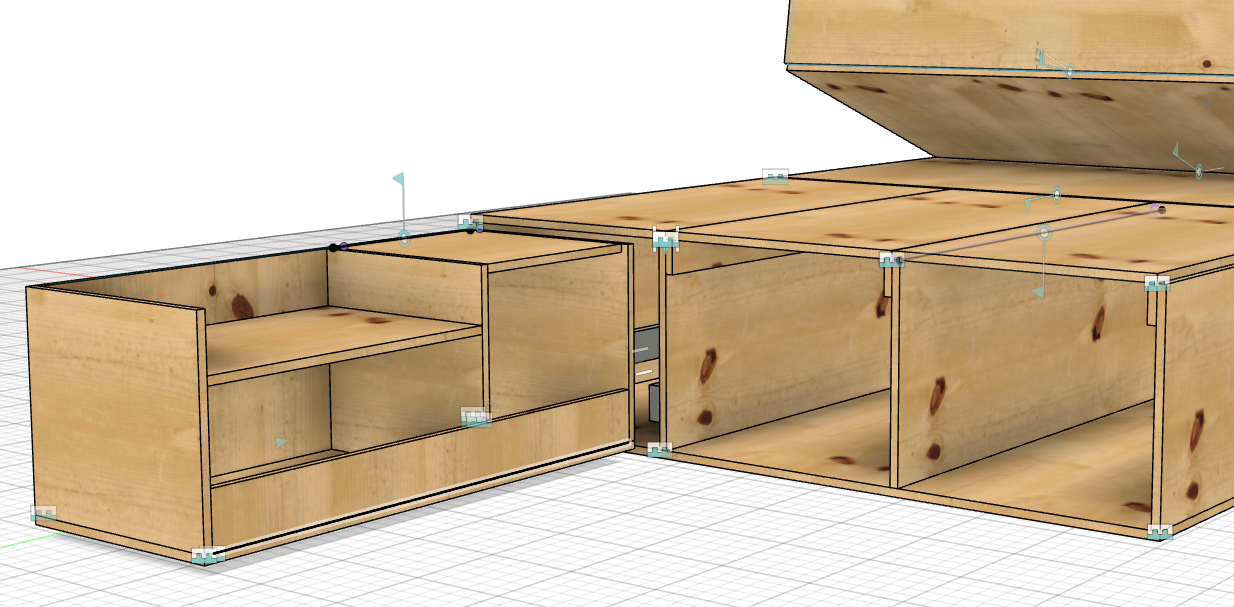

Design of a boot jump

Designing the boot jump was probably the longest part of this project. Although the main idea is very simple and clear from the pictures of the Amdro boot jump – a large box with two empty spaces and a drawer, with a top that “unwraps” as a bed – the devil is in the details, of course. What kind of plywood should I use? How thick should the ply be? Should I make the box entirely out of ply or just planks and blocks? How does the bed unwrap? How do the hinges interfere with the wood? How do I make the joints? Can I put screws through the plies? How do I make a drawer for the kitchen? How high should the seat be? Do I use glue or bolts? And so on, and so on. I didn’t even know exactly what I wanted, and the more design ideas I found on the internet, the more questions I had.

When I got close to drowning in the sea of information that is the internet, I found an interesting post on a forum for conversions of Citroen Berlingo. Gravity, a Welsh user of the forum, created their own boot jump for a Citroen Berlingo, documenting every single step of the process. Not only they created a very similar boot jump to the one produced by Amdro, but they also improved their design by introducing a foldable side of the box that increases floor space when sitting inside.

Armed with patience, the details from Gravity and a load of free time due to lockdown and the climbing gyms being closed, I started creating my own design in Fusion 360.

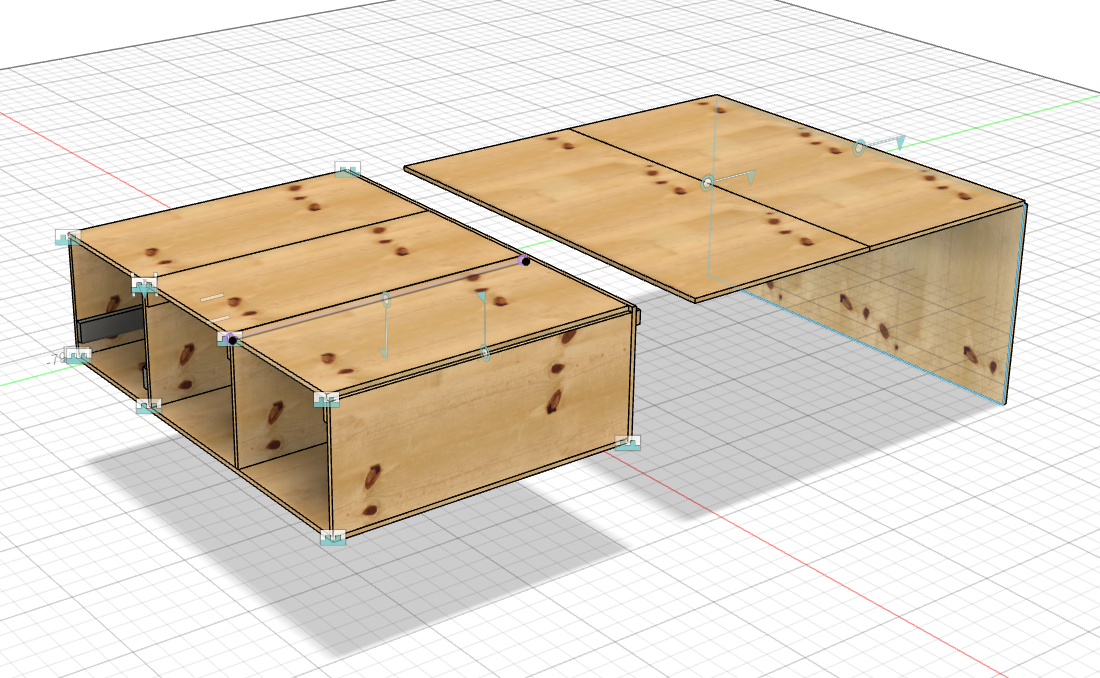

The final design

I looked at a lot of boot jump and micro campervan designs. Google images, Pinterest, Reddit, YouTube and Instagram were all great sources of inspiration. Every time that I saw a new design, I tried to look at their details and figure out how they solved each of the design problems I was facing.

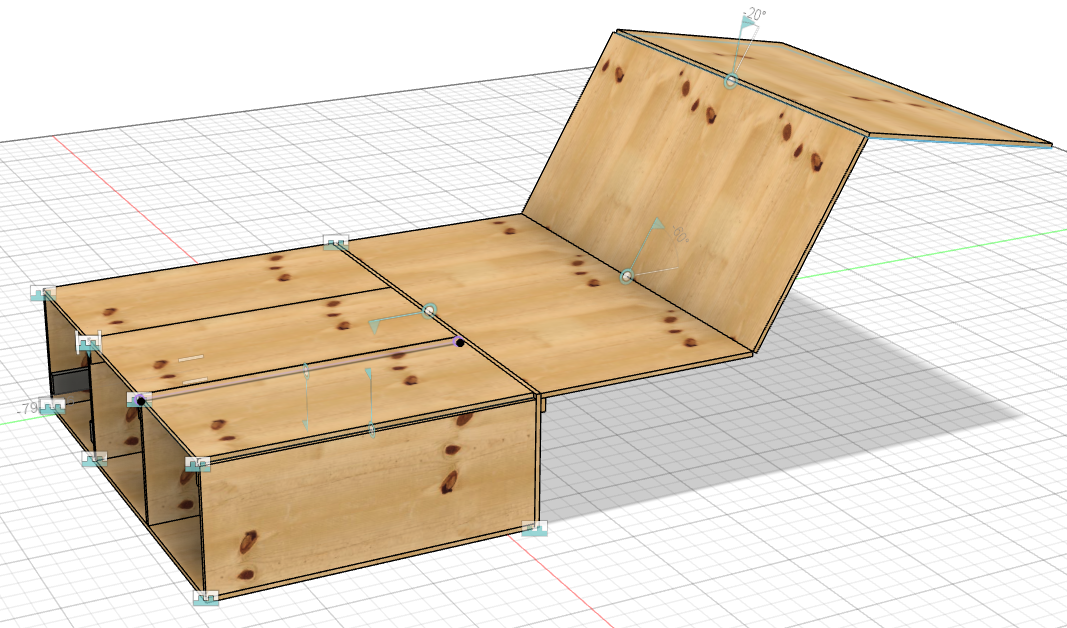

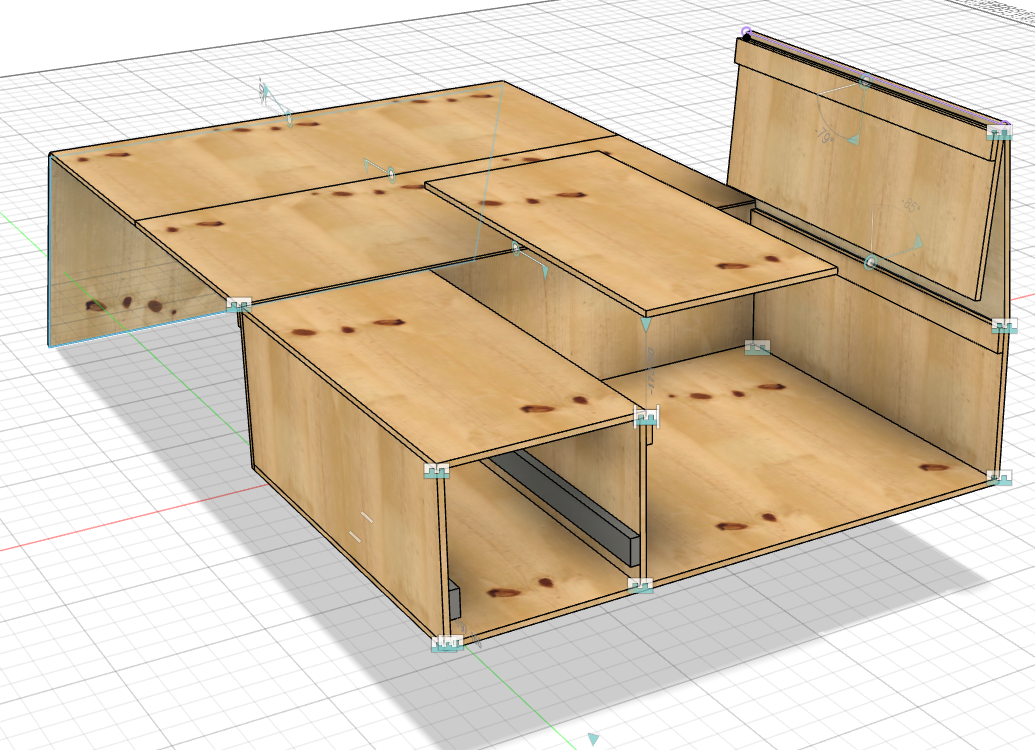

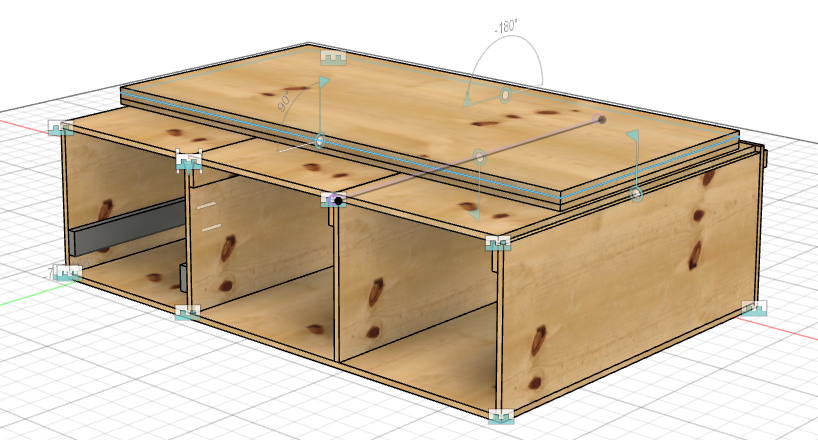

In the end, after talking to my dad, many friends, and people on Reddit, I came up with this design. At this stage, I only focussed on the bed/table box and left the kitchen for a later time. The bed is composed of three different sheets of ply hinged together: two of them compose the bed (together with the main box) while the third one folds down and sits on the floor of the car (behind the front seats). The two boards forming the bed rest almost entirely on the back of the rear seats, which are folded down when the bed is in position (not in the picture). The entire bed is then attached to the main box using toggle latches.

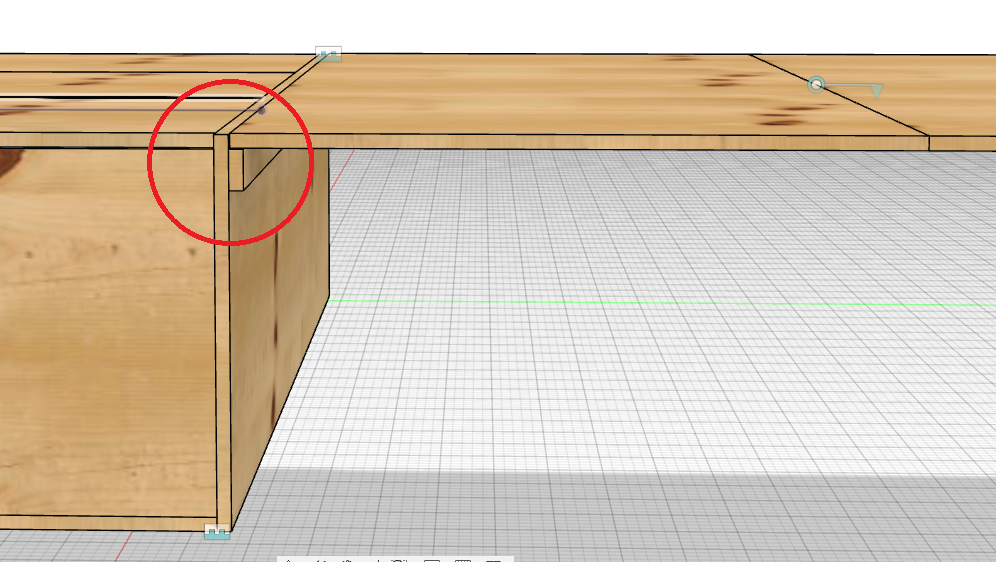

Along the entire length of the main box, I also installed a narrow wooden plank (red circle in the figure) that helps support the bed when latched in position.

When the structure is set up as “sofa mode”, the middle board of the bed folds upwards and the legs bend so they can rest on the headrests of the front seats (not cut to shape in the CAD figure).

Looking at the main box, the lid of the central space is removable and, in bed mode, rests on top of two planks protruding from both sides of the middle box. When removed, it becomes an island table that rests on a removable metal leg that fits together with the base of the box (not pictured in the CAD figure).

The right side of the box can be used as a bench for sitting at the table, or it can be folded away completely to get more floor space.

When not in use, the bed detaches from the main box using the toggle latches, folds back into one piece and slides on top of the main box, so that it can fit entirely in the boot of the car.

The measurements

With all the pieces put together into CAD, it was now time to give my boot jump some real measurements, so that I could get all the pieces cut from the woodshop. My first approach was to keep working in CAD. If I got my hands on a realistic 3D model of the van, I could properly size and test every single part of the conversion before getting it cut. Unfortunately, I could only find models of the exteriors, and when I tried to create my own model, I realised how daunting of a task it would have been. You don’t realise how complex are the shapes and curves of modern cars until you try to model them in CAD!

In lack of alternatives, I decided to take all the measurements manually. To make sure that all the pieces fit together nicely, I simply got all the empty boxes I could from a local supermarket and started creating my simplified mock-up version of the boot jump out of cardboard and tape.

It wasn’t pretty. And it wasn’t stable. But it worked! Using this mock-up version, I could make sure that the box fitted nicely in the boot when the back seats were up, that the bed was lying flat when open and that the height of the box was enough for me to sit upright without touching the roof of the car.

With all the parameters updated in Fusion 360, I was ready to create a cutting list. Thankfully, Fusion 360 has a handy plugin that does it automatically for you.

In terms of wood type, I decided to go for Hardwood Plywood (Q Mark) of 12 mm, which seemed to be solid and durable. A few days after contacting the woodshop, my order was ready to pick up.

If you want the exact measurements of the boot jump, you can download them from here:

Assembly

Now that I had all the pieces for my boot jump, it was time to put them together. But before that, I had to figure out how to deal with the joints. Having basically no experience with woodworking, I started googling “wooden joints” and a whole new world opened in front of my eyes… Biscuit joint, pocket joint, dove tail, tongue and groove… Each with its strengths and complexities, but most importantly, each requiring fancy wood tools that I didn’t have nor intended to buy or learn how to use! The easiest thing would have been a basic butt joint, which simply means flushing two parts together and either screw or glue them. However, screws would have to go in the direction parallel to the plies, which weakens the structure. I also didn’t like the idea of using permanent fixing since I didn’t know if my assembly process was going to work. I mean, even when you follow instructions from IKEA, you often realise you did something wrong and need to undo everything and start from the beginning. And I had no instructions…

After a quick trip to the local hardware store (one of the many, many, trips after that) and some chats, I decided to go for the bolts and nuts solution. I bought a bunch of metal corners, L-shapes, a ton of bolts, nuts, washers, and started putting the entire structure together. For the entire process, the only tool that I had to buy was an electric drill (basic Bosch one for £55) with a set of drill bits and screwdrivers. A couple of wrenches also made my life easier during the entire process.

One of the hardest thing of the assembly was probably putting together the first three pieces, since I had no reference, no stable structure and nothing to work on. Bit after bit, and a whole weekend later, the entire structure started to take shape. During the process, having my laptop open in front of me was immensely helpful and I was so glad I had the model to use as a reference for the assembly. I would definitely recommend that to anyone designing a conversion kit from scratch.

In terms of hinges, I used three different types. For the bed, I used piano hinges, which are really thin and have many holes, so they distribute the pressure on many different points. For the foldable bench, I used standard hinges for the flap side and flush door hinges at the base, so that the weight of someone sitting on the bench is taken by the entire wooden structure and not by the screws holding the hinges.

One last thing that I decided at the very end of the assembly was to use self-locking nuts instead of standard ones. I’m not sure it really made a difference, but it gave me more confidence that the whole structure wasn’t going to disassemble itself due to the vibrations.

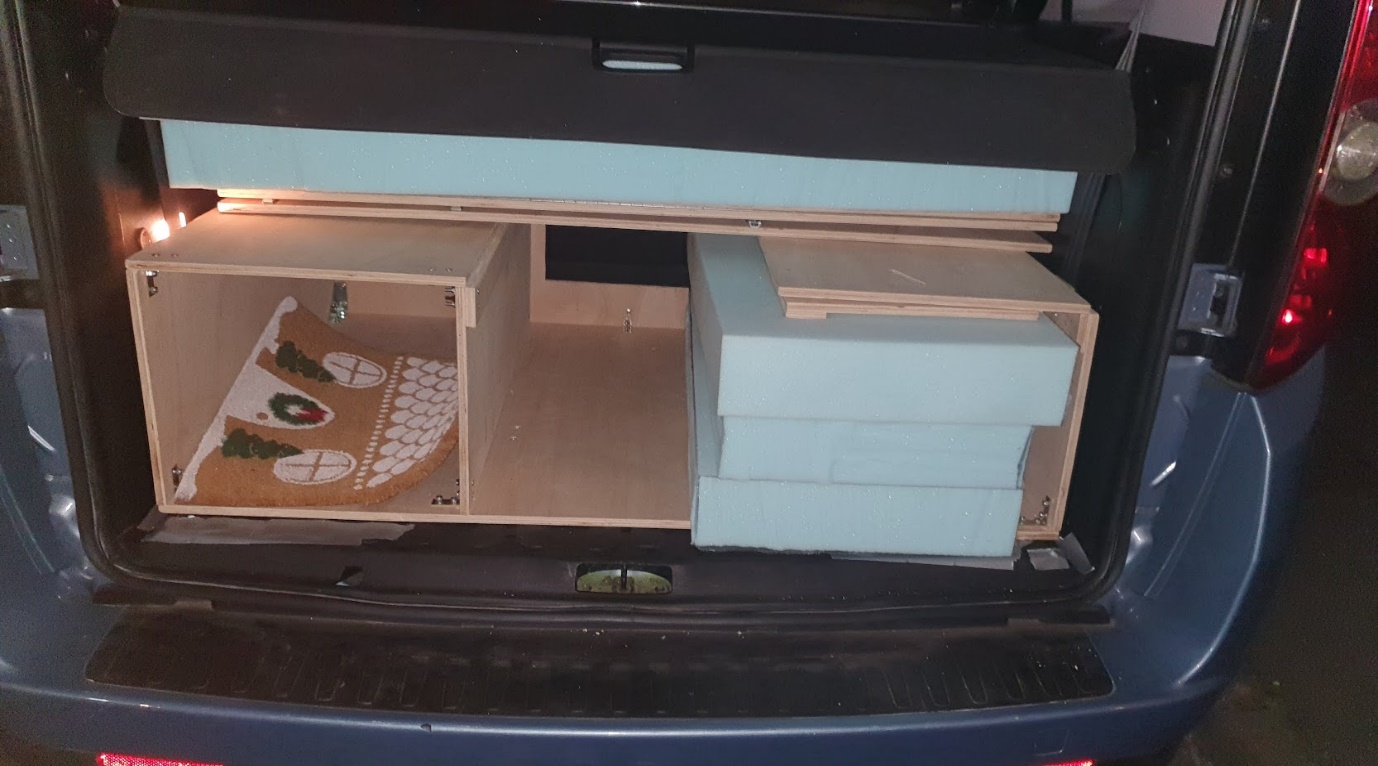

Fitting to the car

Now that I had a semi-rigid structure that I could move around, I could finally put it in the car and see if it fit… and it did!

The next step now was modifying the shape of the leg board of the bed, so that it fitted the shape of the car. Since I couldn’t get this done from the woodshop, I bought a cheap electric jigsaw for £10 and cut it myself. Luckily, this cut didn’t need to be straight nor neat. As long as the board fitted in the leg space of the rear seat, it was just fine. I put the leg board in position, took a few marks for the incuts where the obstacles were, made sure it was symmetric and simply cut a few chunks off it.

At the same time, I also made sure that the board fitted nicely on the headrests of the front seats, so that I could use that board as a backrest for the bench when I’m using it upright.

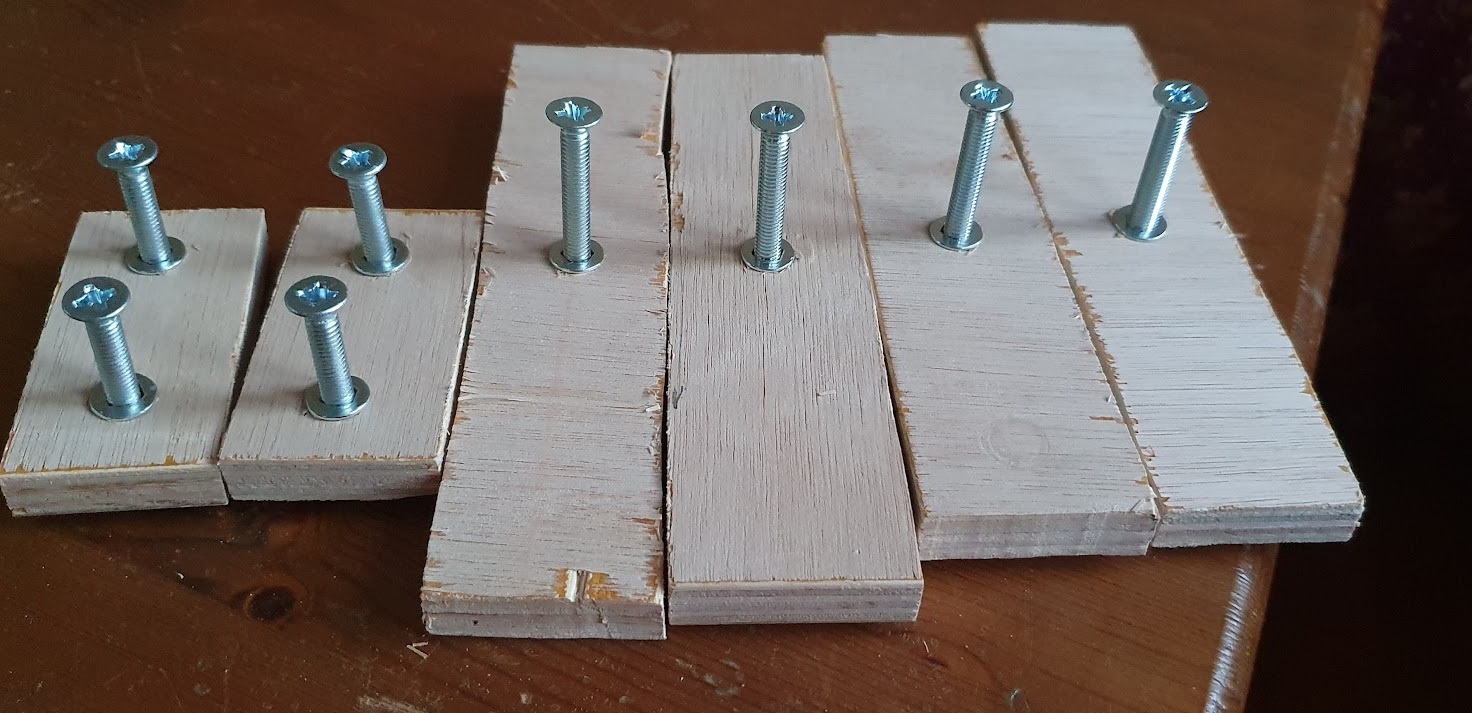

One big issue that I still had to solve though, was how to fix the entire boot jump to the car. The majority of the solutions that I saw online, simply used lateral supports that screw out of the box, press against the side of the boot and keep the box in place. However, the sides of my car are made of cheap flimsy plastic and didn’t really seem suitable for the job. On the other hand, my car came with 7 seats and has some interesting metal inserts on the floor of the boot that I could use to clamp the structure.

I cut a few wooden rectangles that slide under those metal bars and then screwed threaded inserts into them. On the boot jump side, I simply made a few holes matching those inserts, so that I could use removable bolts to fix the box to the car. Making those holes was a bit of a pain, since I couldn’t see the inserts when the box was in. To solve this issue, I just put a reference frame onto the car with some tape and took very precise measurements for the horizontal and vertical position of each of the holes.

Table

The table was fairly easy to install. If you Google “Island Table Leg Set / Kit” you can find dozens of websites that sell standard table kits suitable for campervans. You can find some very fancy ones, but the basic one is just a metal pipe that is tapered at the ends and that fits together with two conical shapes. One goes on the floor, the other one under the table, as simple as that. Since I didn’t want the base of the table to be permanently screwed to the wooden box, I first installed some threaded inserts on the floor of the box and then fixed the table base using bolts.

As a final touch, I bought a couple of metal clips that I screwed on the side of the box and hold the table leg in position when I’m not using it.

Cushions

The most important part of the bed was obviously the mattress. While you could easily use the boot jump with an inflatable mattress, there’s no comparison to how comfortable a real mattress can be. Some companies sell custom made cushions for vans, using the materials and shapes of your choice, but they aren’t cheap. The cheapest solution that I could find was buying the foam for the mattress, cut it myself to shape and then sew the upholstery to cover them. But which mattress? All the standard mattresses that I could find weren’t quite the right shape to fit the entirety of my bed. Luckily, I found a really good and cheap company that makes foam mattresses cut to size, eFoam. On their website, you can order whichever custom size you want, from 2” to 8” thick. I decided to go for 4” high density (firm) foam for £134, and it’s just perfect.

The next step was cutting it to shape, so that I could have two main cushions for the bed, and three smaller ones for the benches and the top of the table. I simply laid the mattress over the bed and marked the points where I wanted to cut. From other conversions that I saw, people seemed to have a really easy time cutting the foam using electric bread knives. I’m not really sure why people own electric bread knives, but I couldn’t find any, so I had to cut it by hand. And it wasn’t easy… Cutting a giant wobbly structure trying to follow a straight line is a harder problem than you might think, and the result wasn’t that neat…

The good news is that the cushions were going to be covered with the upholstery and no one is ever going to see how bad those cuts are.

As for the upholstery, I didn’t do it myself, but I asked a friend with a sewing machine, Frida. She’d never done anything like this before and didn’t have much experience with the sewing machine either, but with a bit of patience and a lot of YouTube tutorials, we managed to get all the cushions done. For the fabric, I ordered it from Lushfabric and spent around £67 for 7.5 metres of material.

Blinds

The greatest thing about converting a car into a van is that it has a lot of windows, and you can enjoy the view from wherever you sit inside. However, the worst thing about converting a car into a van is that it has a lot of windows that you need to cover when you go to bed! Either for privacy or just to make it dark, you want to cover those windows. Once again, they do sell pre-made thermal blind kits for all the windows of my car, but they come at a hefty price tag (£150!). For a much cheaper price, I managed to buy a £5 corrugated plastic sheet from B&Q that is typically used to insulate roofs and stuff. I simply cut it to shape for each window and sled it through the glass seal to keep it in place.

In terms of making it dark and insulated, this works very well. However, sliding those panels into place through the glass seal is a real pain and it’s the last thing you want to do when you’re tired at night and just want to sleep. In the future, I’m planning of adding some magnets to them (keeping them in place with duct tape) so that I can simply chuck them at the window and they will stay in place by themselves.

Finishing touches

At this point, the boot jump was ready for its first night out. I could use it bed mode

I could use it in “sofa mode”

and I could pack the entire structure in the boot without taking any space from the rest of the car

All I needed was a couple of finishing touches before getting on the road. I used a single coat of varnish on the entire structure to protect it, and a triple coat on the table, so that it wouldn’t get too dirty. I also installed some fairy lights on the top shelf of the car, so that I didn’t need to use the car battery for illumination. To make sure I didn’t depend on stupid AAA batteries for the light, a bought a couple of USB DC-DC 5V to 1-24V adjustable adapters. They’re really neat (and cheap! Less than £3 on AliExpress), you plug them into a USB (like a battery pack) and they have a potentiometer to adjust the voltage in output. I simply cut off the wires from the fairy lights, screwed them into the adapter and ended up with USB-powered adjustable fairy lights. To hold them in place on the shelf, I simply used foldback clips (not yet installed in the picture).

At this point, the van was ready for its first night out!

The kitchen

The next chapter of the conversion concerns the kitchen. I only worried about this later, since I didn’t know exactly what I needed. But after a few months of vanning, all I knew is that I definitely needed a kitchen. I wasn’t sure exactly what this would have looked like, but I liked the idea of it being a drawer that sled off the side box of the boot jump.

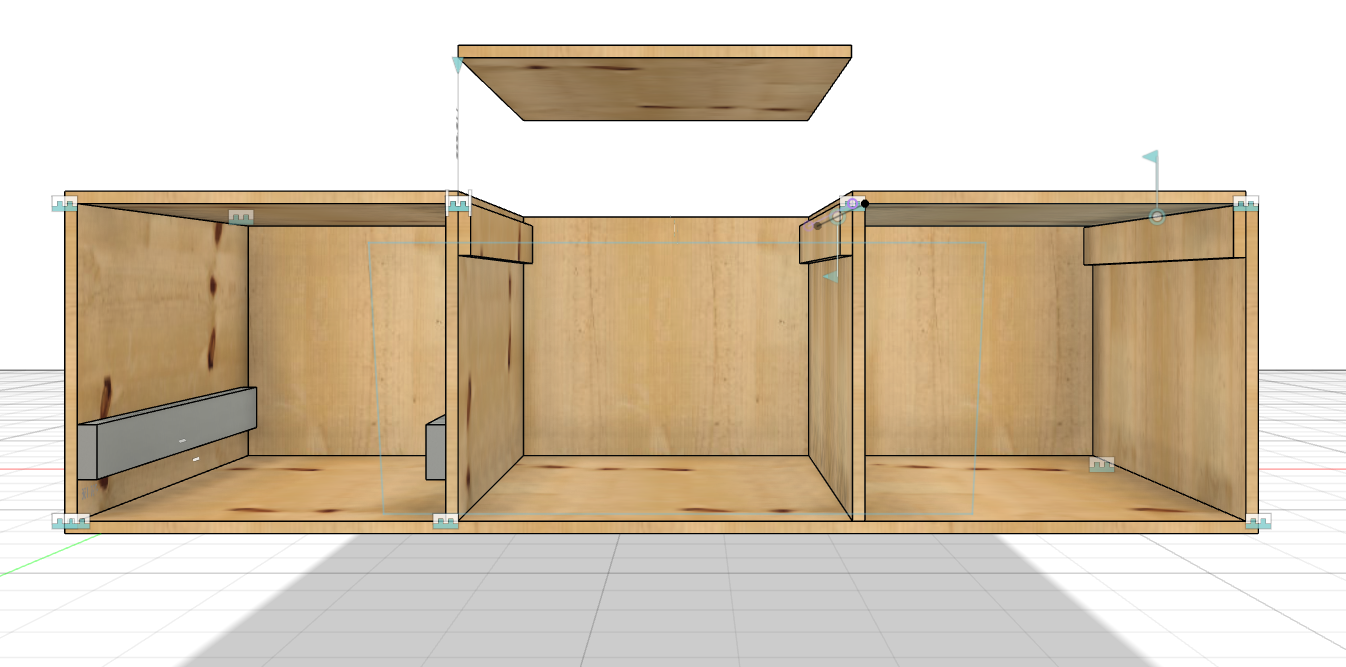

Since the measurements and the cuts needed to be very precise for a drawer, I got back onto Fusion 360 and came up with this basic design:

The main requirement for this design was that I could fit a small double stove camping burner on the main shelf, so I took a few measurements from potential candidates and made the kitchen drawer around them.

While designing the drawer, I also had to make sure that the pieces would fit together nicely with the runners, which I hadn’t quite bought yet. A quick trip to a few hardware stores revealed that runners are sold in standard lengths, and of course, my box didn’t fit any of those standards. Luckily, an online website called Furnica was selling a wider variety of runners and had one that was almost the right size for me, 750 mm vs 788 mm of my boot jump. Using these runners meant the drawer wouldn’t open for its entire length, but 4 cm less is not a big deal, so I bought them for ~£40.

With the exact dimensions of the runners in place, I could finalise all the measurements of the drawer and make another cut list to send to the woodshop. To my surprise, when I inquired about this new order (that was meant to be much smaller than the first one), they took a very long time to reply, and when they finally got back to me, they asked me a whopping £106!! Considering that the entire boot jump cost me £117 and it was twice the number of cuts and material, that took me completely out of the blue. Luckily, my local hardware store came once again to save me with a much cheaper quote of just £22, service included!

Assembly

By the time I started assembling the kitchen drawer I felt much more confident about what to do. However, I had never installed a drawer before, and I wasn’t sure how it worked. Do I put the fixed element first or the moving one? How do I make sure they’re aligned? How do I screw them in without interfering with their function?

As always, there are YouTube tutorials for everything, including how to install drawers on wooden furniture. I still had a few issues with interference between some screw heads and the runners, but after a bit of debugging, I managed to get it to work smoothly. I’m also very grateful for my past decision of not using glue to fix the entire structure together, otherwise it would have been a terrible pain to install the drawer without access from the top!

In the end, I also decided to change the layout of the shelves. Since I didn’t plan on buying a full-size burner anymore, I mounted the shelves on the top of the drawer to maximise the space inside. I also fixed them with some simple dowels, so that they would stay open for access and I could remove them completely if I need to.

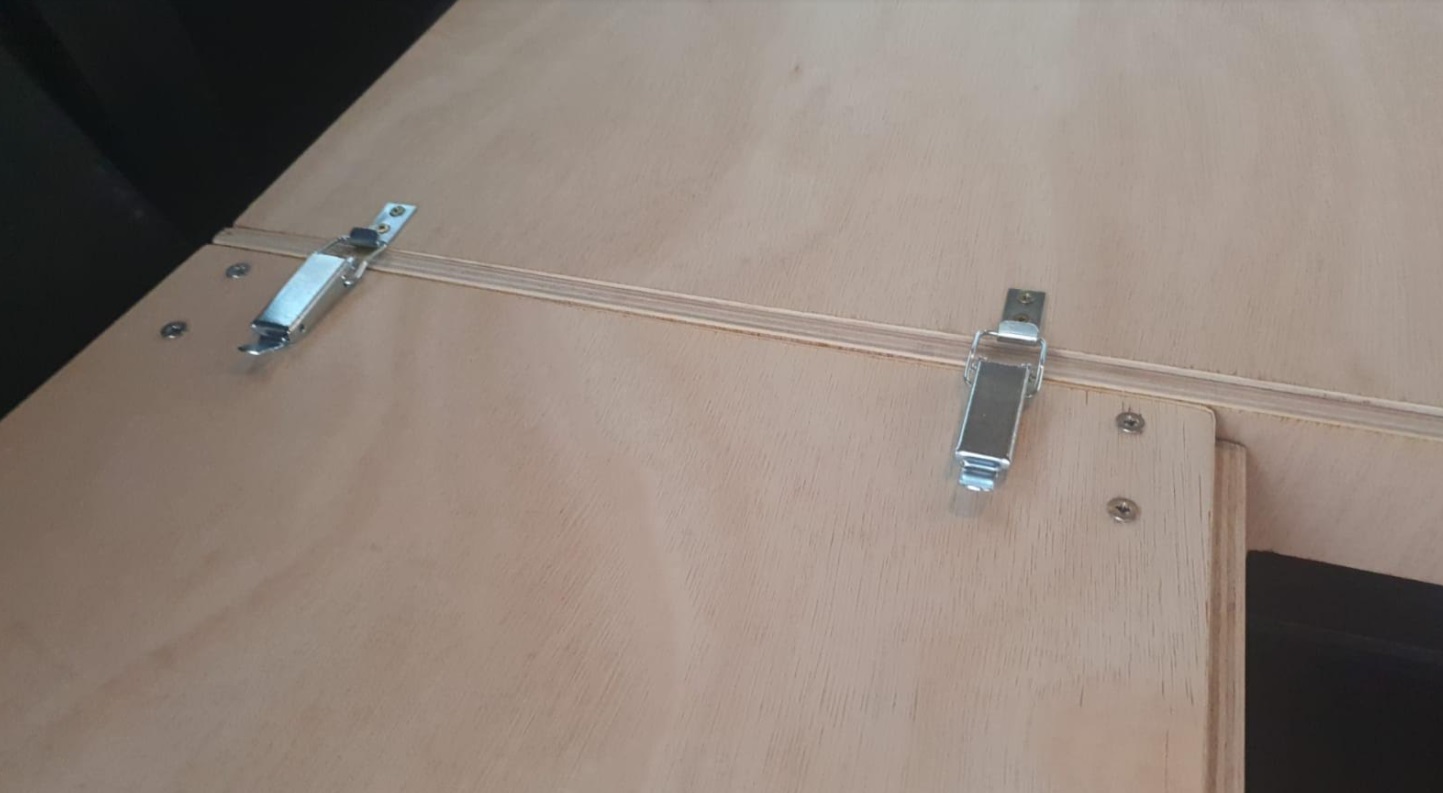

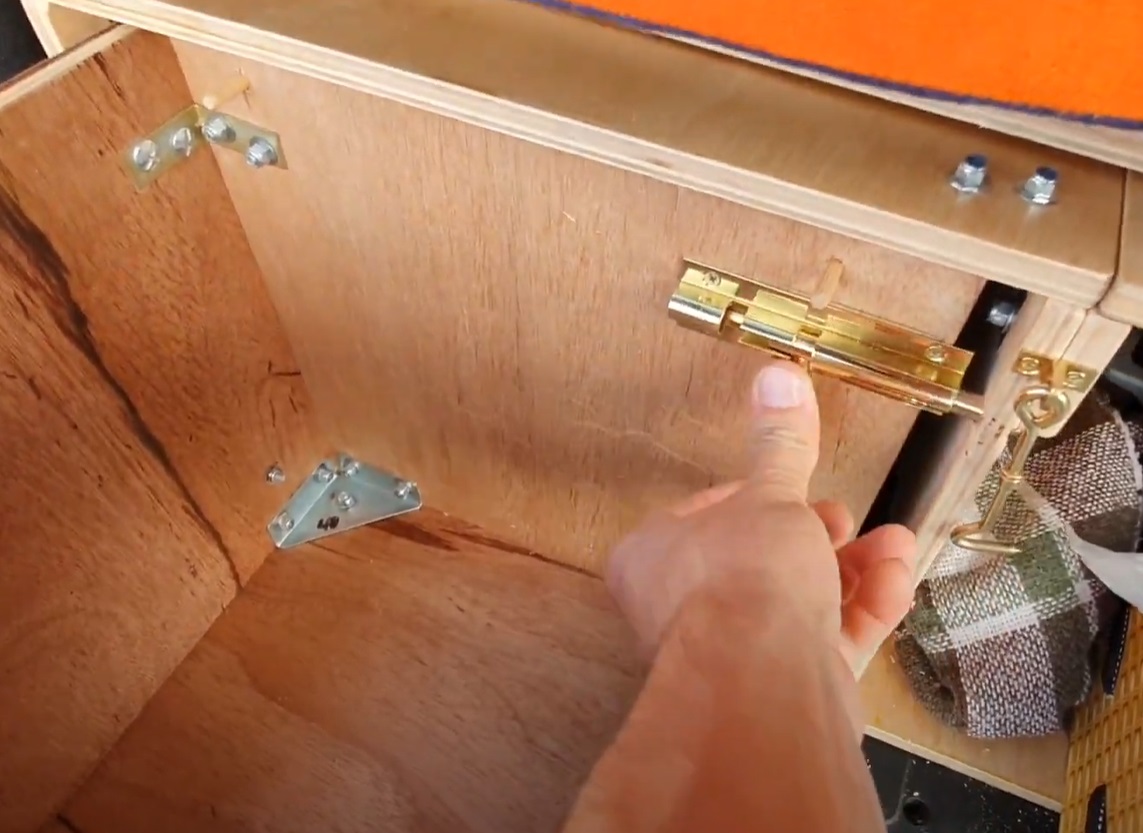

Locking mechanism

One problem that I had to fix at this point was how to keep the drawer open or shut when I’m driving or parked on a hill. I wanted to find a smart and elegant solution that would work in both cases, keeping it open when it’s open, and shut when it’s shut, but after my usual trip to the local hardware store, I couldn’t find anything inspiring that worked for both. The easiest (and cheapest) solution that I found was to use two different door latches – a simple hook and eye latch to keep it shut on the outside and a sliding latch on the inside to keep it open.

Extremely simple, yet extremely effective.

As a final touch, I also installed an additional shelf on the front door of the drawer, to have some extra space when cooking. The shelf is attached to the bottom drawer using flush hinges and it stays in place thanks to a drop-down flap stay hinge installed on the side. An additional toggle latch on the side of the drawer keeps the shelf in place when closed.

Now the van is really ready for the next adventures!

Conclusions

Final bill

Here’s a summary of what I spent for the entire conversion. I don’t have the individual prices for each item but I added a description for what a bought on each trip to the shop.

| Description | Where | Cost |

| Bosch power drill | B&Q | £55 |

| Electric Jigsaw | ASDA | £10 |

| Wood + cutting service for main box (bed and table) | Robbins | £118 |

| Screws, bolts, nuts, angle brackets, hinges, sandpaper | Bishopston Hardware | £32 |

| More screws, more hinges, varnish, brushes, wood glue | Bishopston Hardware | £58 |

| Foam for mattress | eFoam | £134 |

| More L-shapes, toggle latches and bolts | Bishopston Hardware | £18 |

| Fabric for upholstery | Lush Fabric | £67 |

| Drill bit and more screws | Bishopston Hardware | £7 |

| Island table leg and supports | eBay | £30 |

| Insulation sheet for blinds | B&Q | £5 |

| Drawer runners | Furnica | £41 |

| Wood + cut kitchen drawer | Bishopston Hardware | £22 |

| Flap hinge stay, latches, drawer handle | Bishopston Hardware | £24 |

| Total | £621 |

While I was being cautious with my spendings when building this conversion, I didn’t always choose the cheapest solution. I spent a total of around £600 for the conversion, but you can spend much less if you’re happy to compromise. If you already have access to power tools, you’re happy to sleep on an inflatable mattress and don’t mind having a simple shelf as a kitchen, you can probably cut down the costs to £200-£300 and still have a fully working boot jump.

Shop local

One of the things that I learnt during this build is that local hardware stores are fantastic. After doing a comparison with larger stores like B&Q, I quickly realised that they are not only cheaper and very well stocked with any sort of bits and pieces you might need, but people working there are also much more knowledgeable about what they’re selling. They will often have the time and patience to hear your problems and help you to solve them, contrarily to larger chains where employees are constantly running around and don’t really seem to have time for customers (in my personal experience). Another big advantage of local hardware stores is that they often sell things by unit. Do you need just 2 slightly larger bolts? You can go and buy them for a few pennies, no need to buy a whole 200x box!

What I’d do differently

They often say that you build your first van for your enemy, your second one for your friend and the third one for yourself. Honestly, after spending so much time doing research and planning in advance, I feel like this doesn’t really apply to my van and I’m very happy with what I built. If I could start all over again, I would surely be quicker, more precise in the assembly and save myself a few extra holes that I ended up drilling, but there wouldn’t really be any major flaw I’d redesign.

One potential problem I could have that I have yet to experience is dealing with rainy days. While I can comfortably spend the day indoors, accessing the kitchen drawer for food and cutlery requires me to get out of the car and open the boot, which might not be ideal. I could easily replace the L-brackets of the bench with hinges and latches, but I’m afraid the whole structure would lose rigidity. On the other hand, since the boot door opens up vertically, it works perfectly as a roof in case of bad weather, allowing me to potentially cook and eat outside even when it rains. Amdro sells an entire tent that attaches to the boot door and gives you even more space, but it costs £430 just for the tent and it’s not very stealthy. If I really feel the need, for the future, I could always buy a plastic sheet, cut it to shape, attach it with magnets/clips to the boot door and get myself a gazebo.

Cooking indoors is also a possibility, especially using the simple camping stove kit that I’ve got. I’ve done that once by simply putting the table between the two benches, so that It’s not too high and close to the roof, although I still opened the boot being scared of potential CO/CO2 build-up.

Storage

Storage in the van is a bit of an issue. I have travelled with the van for a whole week with climbing gear and I definitely felt the lack of extra space. While all the food and water can stay under the table and bench, all the clothes, shoes and climbing gear were constantly moved around from the front seat, while sleeping, to the bottom of the rear seat, while driving. The original design of the boot jump from Amdro improves the storage problem by removing the entire rear bench of the car and adding an additional flap on the bed to keep it in place. While this surely frees up a lot of space, it requires you to unbolt the entire bench, which can be time consuming and potentially unsafe if you don’t know what you’re doing.

My solution for the future is probably going to be a roof box. It can be as big as you need and adds an enormous quantity of space without modifying the car at all. It also works as a good replacement for the boot space that you lose by keeping the boot jump in the car all the time. The only problem is that they’re expensive. Like £300-600 expensive.

Tips for a good night sleep

On my first night out I didn’t sleep really well as I was constantly worried that “something” might happen. If you don’t feel confident wild-vanning, stopping at a campsite can buy you some peace of mind, but I always found that parking in the most remote locations is much more pleasant and rewarding, especially when you get used to it. To find an ideal spot where to sleep I often start with park4night, which has a handy Android app with offline maps. The app shows you a variety of possible locations where to spend the night, with pictures, description of facilities and even reviews. However, I often found myself finding my own spots in the middle of nowhere. I usually drive towards the countryside, maybe on a nice hill with a view and then get through the most isolated B-roads to find a large enough layby area where to spend the night.

One essential requirement to have a good night sleep is to park as level as you possibly can. On my first night, I parked on a slope thinking that it was flat enough. Well, it wasn’t, and I spent the entire night crawling back up the bed. Now I got a better idea of what “flat” should look like but a car inclinometer, usually found in off-road vehicles, can be a cheap investment for finding the best angle for the perfect night sleep.

Sleeping bags are also very handy for sleeping in the van, since they pack up very small. However, having a full-size duvet taken from the bed at home, with real pillows, will provide you with the best night sleep you can dream of!

Outro

And this is it. I hope you found some parts of this article interesting and maybe convinced you to buy a van as well. The freedom of being able to sleep wherever you want, whenever you want, is one of the best feelings you can experience.

Here are some pictures of the final conversion and the steps to set it up. It took me exactly 3 minutes and 20 seconds to go from zero to sofa mode with the table open (probably just 2 minutes for bed mode).

Following are a few more pictures of some picturesque places where I spent the night: